Lean and Six Sigma methodologies have become indispensable tools for industries seeking to enhance operational efficiency, reduce waste, and improve overall quality. Across Australia, businesses in sectors such as healthcare, manufacturing, and IT are leveraging these strategies to stay competitive in an increasingly dynamic market. This guide explores the top 10 industries benefiting from Lean and Six Sigma. It highlights how CBIS can provide the training necessary to equip organisations with the skills and knowledge to achieve process excellence in the coming year.

1. Healthcare

Improving Patient Outcomes

Lean and Six Sigma have transformed healthcare delivery by streamlining processes, reducing medical errors, and improving patient care outcomes. Hospitals and clinics across Australia use these methodologies to minimise waiting times, optimise resource allocation, and enhance patient satisfaction.

Case Example

For example, value stream mapping helps healthcare facilities identify bottlenecks in patient flow, reducing delays and improving service delivery.

2. Manufacturing

Optimising Production Efficiency

Manufacturing has long been a primary adopter of Lean and Six Sigma methodologies. These methodologies reduce defects, optimise production processes and lower operational costs. Australian manufacturers particularly benefit from Lean’s waste elimination principles, ensuring efficient use of materials and labour.

Case Example

DMAIC (Define, Measure, Analyse, Improve, Control) frameworks enable manufacturers to identify inefficiencies in assembly lines and implement corrective actions, significantly improving product quality.

3. Information Technology (IT)

Enhancing Software Development

In the IT sector, Lean and Six Sigma are instrumental in improving software development processes and reducing coding defects. By applying principles like root cause analysis, IT firms can enhance system reliability and reduce downtime.

Case Example

Lean’s focus on eliminating non-value-added activities is widely used in Agile software development, improving project timelines and resource management.

4. Finance and Banking

Streamlining Operations

Australian financial institutions utilise Lean and Six Sigma to improve customer service, streamline loan processing, and reduce operational costs. These methodologies are particularly effective in identifying inefficiencies in transaction workflows and fraud detection systems.

Case Example

Banks implementing Six Sigma can reduce errors in financial reporting and compliance processes, ensuring adherence to regulatory requirements.

5. Retail

Improving Customer Experience

Retailers apply Lean and Six Sigma to optimise supply chain logistics, improve inventory management, and enhance customer satisfaction. Retailers can offer more consistent service and improve product availability by reducing process variability.

Case Example

Six Sigma’s statistical analysis tools help retail chains minimise stockouts and overstock situations, ensuring better inventory turnover.

6. Logistics and Supply Chain Management

Reducing Waste and Delays

Logistics companies in Australia benefit from Lean and Six Sigma by identifying inefficiencies in shipping routes, warehouse management, and delivery schedules. These methodologies help streamline operations and reduce costs associated with delayed shipments.

Case Example

Value stream mapping allows logistics providers to visualise supply chain processes, enabling them to optimise transportation and inventory handling.

7. Education

Enhancing Administrative Processes

Universities and schools are adopting Lean and Six Sigma to improve administrative efficiency and enhance student services. These tools help reduce paperwork, streamline enrolment processes, and improve resource allocation.

Case Example

Educational institutions use Six Sigma to optimise the scheduling of classes and resources, resulting in better facility utilisation and improved student satisfaction.

8. Construction

Improving Project Management

Lean and Six Sigma methodologies are used in the construction industry to reduce project delays, control costs, and improve safety. Australian construction companies can achieve higher project delivery success rates by applying these tools.

Case Example

Lean construction practices like pull planning and Last Planner Systems help align project teams and reduce wasted effort.

9. Energy and Utilities

Maximising Resource Efficiency

The energy sector leverages Lean and Six Sigma to optimise resource utilisation and improve maintenance operations. These methodologies are also used to enhance compliance with environmental and safety regulations.

Case Example

Six Sigma’s focus on defect reduction helps utility providers identify and address inefficiencies in energy distribution systems.

10. Hospitality

Enhancing Guest Satisfaction

Lean and Six Sigma enable hotels and restaurants to deliver superior customer experiences by reducing service variability and improving operational efficiency. These methodologies are particularly useful in streamlining kitchen workflows and reservation systems.

Case Example

Hotels applying Lean tools can optimise housekeeping schedules and reduce check-in and check-out times, enhancing guest satisfaction.

How CBIS Can Help Businesses Gain a Competitive Edge

CBIS provides comprehensive Lean and Six Sigma training designed to equip businesses with the tools they need to excel in their respective industries. With expert-led courses, CBIS helps organisations:

1. Tailor Training to Industry Needs

CBIS offers customised training programs that align with your industry’s specific challenges and objectives.

2. Develop Key Skills

CBIS ensures participants gain practical knowledge of Lean and Six Sigma tools, such as DMAIC, root cause analysis, and value stream mapping.

3. Achieve Certifications

From Yellow Belt to Black Belt certifications, CBIS provides structured pathways to master Lean and Six Sigma methodologies.

4. Drive Measurable Results

With CBIS training, businesses can confidently implement process improvement strategies that reduce costs, improve efficiency, and increase customer satisfaction.

Conclusion

From healthcare and manufacturing to IT and retail, industries across Australia are reaping the benefits of Lean and Six Sigma methodologies. These tools improve efficiency and quality and provide businesses with a significant competitive edge. By partnering with CBIS for training and certification, organisations can equip themselves with the knowledge and skills needed to thrive in 2025 and beyond. Now is the time to invest in Lean and Six Sigma training to ensure your business is ready for future challenges and opportunities.

Contact us today to learn more about our Lean Six Sigma training programs and to empower your team with Lean Six Sigma training. Our expert trainers are dedicated to helping your employees unlock their full potential and drive individual and organisational success.

What is DFSS? Design for Six Sigma is used to perfect products and processes before...

What is DOE? In general usage, design of experiments (DOE) or experimental design is the...

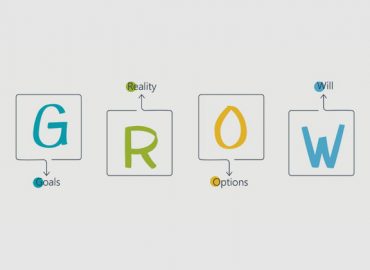

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma is a powerful method for improving existing products, processes and services. One...

Introduction In our lean six sigma projects, too often we spend all our time on...

What is a Kaizen Blitz? Kaizen definition has been Americanised to mean “Continual Improvement.” A...

Overview Layout planning is one of the most important aspects of Lean manufacturing. In some...

As global competition continues to grow, the pressure to improve becomes more and more intense....

What is SMED? SMED is the term used to represent setup time and is often...

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

Introduction Value Stream Map (VSM) is a diagram of every step involved in the material...

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.