In an era where environmental sustainability is a critical priority, businesses are increasingly adopting strategies to reduce waste, conserve resources, and minimise their ecological footprint. Lean Six Sigma, a methodology traditionally associated with process improvement and efficiency, plays a pivotal role in helping organisations achieve these goals. By eliminating waste and optimising processes, Lean Six Sigma empowers businesses to integrate sustainability into their operations without compromising profitability. This guide explores how Lean Six Sigma methodologies contribute to environmental sustainability and provides practical steps for implementation.

Understanding Lean Six Sigma and Sustainability

Lean Six Sigma combines two powerful methodologies:

- Lean: Aims to eliminate waste and maximise value for customers.

- Six Sigma: Focuses on reducing variation and improving process quality.

Together, these principles enhance operational efficiency and contribute to sustainability by addressing resource inefficiencies and waste generation. As defined by Lean principles, waste includes anything that does not add value to the end customer, such as excess materials, energy use, and time.

How Lean Six Sigma Drives Environmental Sustainability

1. Reducing Resource Waste

Lean Six Sigma identifies and eliminates non-value-added activities that consume resources unnecessarily. For example:

- Material Waste: Processes that result in overproduction, defective products, or excess inventory often lead to material wastage. Lean Six Sigma tools like value stream mapping help identify inefficiencies and optimise resource use.

- Energy Efficiency: Inefficient machinery or overextended production processes consume excess energy. By streamlining workflows, businesses can lower energy consumption.

2. Minimising Defects and Rework

Defective products increase operational costs and contribute to environmental harm through wasted materials and energy. Six Sigma focuses on reducing defects, improving product quality, and minimising rework, reducing the overall environmental footprint.

3. Enhancing Supply Chain Sustainability

Lean Six Sigma methodologies optimise supply chains by reducing unnecessary transportation, overstocking, and inefficient scheduling. This reduces fuel consumption, lowers carbon emissions, and promotes sustainable sourcing.

4. Encouraging a Culture of Continuous Improvement

Sustainability is not a one-time effort; it requires ongoing commitment. Lean Six Sigma fosters a culture of continuous improvement, encouraging employees to identify and implement environmentally sustainable practices over time.

5. Supporting Regulatory Compliance

Adhering to environmental regulations is crucial for sustainable business practices. Lean Six Sigma’s data-driven approach ensures businesses meet compliance standards by systematically addressing inefficiencies that may lead to violations.

Steps to Implement Lean Six Sigma for Sustainability

1. Define Sustainability Goals

- Align Lean Six Sigma initiatives with the organisation’s environmental goals, such as reducing carbon emissions, conserving water, or minimising waste.

- Use the Define-Measure-Analyse-Improve-Control (DMAIC) framework to structure sustainability projects.

2. Conduct a Waste Audit

- Perform a comprehensive audit to identify sources of waste across processes, including material, energy, and time.

- Engage cross-functional teams to gather insights and uncover hidden inefficiencies.

3. Leverage Lean Tools

- Value Stream Mapping: Visualise processes to identify waste and areas for improvement.

- 5S Methodology: Organise workspaces to enhance efficiency and reduce resource usage.

- Kaizen Events: Focus on short-term improvements with a significant impact on sustainability.

4. Optimise Energy and Resource Use

- Streamline processes to reduce energy consumption, such as adjusting production schedules to align with energy-saving opportunities.

- Implement water and material-saving techniques in operations.

5. Monitor and Analyse Data

- Six Sigma tools like control charts and root cause analysis are used to monitor sustainability metrics and address deviations.

- Measure progress using key performance indicators (KPIs), such as waste reduction percentages or energy savings.

6. Engage Employees

- Provide Lean Six Sigma training to employees, emphasising the link between process improvement and sustainability.

- Encourage team members to propose eco-friendly solutions as part of ongoing improvement efforts.

7. Collaborate with Suppliers

- Work with suppliers to adopt sustainable practices, such as using recyclable materials or optimising delivery routes.

- Apply Lean Six Sigma principles to improve supply chain transparency and efficiency.

Examples of Lean Six Sigma in Sustainability

1. Manufacturing

A manufacturing company uses Lean Six Sigma to reduce defects in production, cutting material waste by 20%. The company also lowers its carbon footprint by optimising energy use in machinery.

2. Healthcare

A hospital implements Lean Six Sigma to streamline inventory management, reduce excess medical supplies, and minimise waste. The initiative also cuts energy use by optimising operating room schedules.

3. Retail

A retail chain applies Lean Six Sigma to optimise delivery transportation routes, reducing fuel consumption and emissions by 15%.

Maintaining Sustainability with Lean Six Sigma

To sustain environmental benefits, organisations must embed Lean Six Sigma principles into their culture:

- Continuous Monitoring: Regularly assess sustainability KPIs and make adjustments as needed.

- Employee Engagement: Foster a culture where employees actively identify and implement sustainable solutions.

- Leadership Commitment: Ensure leadership prioritises sustainability and provides resources for ongoing Lean Six Sigma projects.

Conclusion

Lean Six Sigma is a versatile methodology that extends beyond efficiency and quality improvements to address pressing environmental challenges. Reducing waste, minimising defects, and optimising resource use enables businesses to achieve sustainability goals while maintaining profitability; for organisations committed to driving sustainable business practices, adopting Lean Six Sigma offers a structured and effective pathway to a greener future.

Contact us today to learn more about our Lean Six Sigma training programs and to empower your team with Lean Six Sigma training. Our expert trainers are dedicated to helping your employees unlock their full potential and drive individual and organisational success.

What is DFSS? Design for Six Sigma is used to perfect products and processes before...

What is DOE? In general usage, design of experiments (DOE) or experimental design is the...

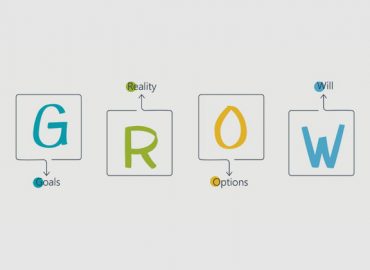

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma is a powerful method for improving existing products, processes and services. One...

Introduction In our lean six sigma projects, too often we spend all our time on...

What is a Kaizen Blitz? Kaizen definition has been Americanised to mean “Continual Improvement.” A...

Overview Layout planning is one of the most important aspects of Lean manufacturing. In some...

As global competition continues to grow, the pressure to improve becomes more and more intense....

What is SMED? SMED is the term used to represent setup time and is often...

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

Introduction Value Stream Map (VSM) is a diagram of every step involved in the material...

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.