Introduction

Value Stream Map (VSM) is a diagram of every step involved in the material and information flows needed to bring a product from order to delivery. It is a lean manufacturing or lean enterprise technique used to document, analyse and improve the flow of information or materials required to produce a product or service for a customer.

It was originated by Taiichi Ohno at Toyota in the 1960s as his basic level of mapping identified wasted time and actions in the manufacturing process. In his words – “All we are doing is looking at the timeline from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that timeline by removing the non-value-added wastes.” (Ohno, 1988)

In the more recent version, VSM has been used for business process re-engineering to identify unnecessary tasks and resources labelled as wastes, eliminate the wastes from the process, simplify the process and consequently increase the efficiency of the business.

Application of VSM?

In an ideal process, materials and information flow smoothly and with a steady pattern. This process excludes the non-value-added steps (waste). The value defines by an internal or external customer who uses the output of the steps of the process. By definition, the value-added step physically changes the process, is done right the first time and the customer is willing to pay for it.

Waste is one of the seven wastes identified by Toyota. These are:

- Overproduction: Production of a product or service at a faster, sooner and more than needed

- Waiting: Time lost when people, materials, tools or machines are waiting

- Transportation: Unnecessary movement of what flows in the process – materials, products, paperwork and information

- Over-processing: Doing more than minimum required to transform the material into an acceptable product

- Inventory: Any material in excess of the one-piece required for the next step in the production

- Motion: Movement of people or machines that do not add value to the product

- Defect: Any aspect of a product or service that does not conform to customer needs. This can result in rework or rejection.

Advantages of Value Stream Mapping

- It provides a common language for talking about processes.

- Unlike other mapping tools, It shows the linkage between the information flow and the material flow.

- It helps you visualise more than just the single-process level.

- It shows the sources of waste in the value stream.

- It ties together lean concepts and techniques.

- It forms the basis of an implementation plan

- It gives more details than other mapping tools such as non-value-added steps, lead time, distance travelled, the amount of inventory, and so on.

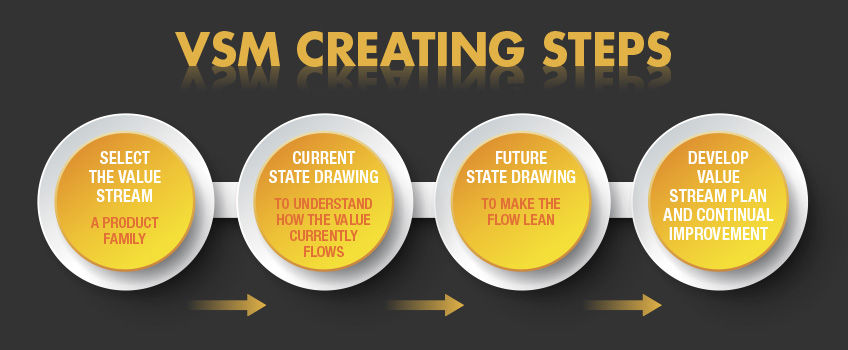

VSM Creating Steps

1. Select the Value Stream ( a product Family)

Firstly, we need to select one value stream (product family) that we want to map. A family is a group of items that pass through similar processing steps and over common equipment. We need to focus on family instead of drawing VSM for individual products. Create Product Family Matrix if your mix is complicated.

The product family can be selected by customer or customer category, by product or product family, by plant, by service – production, spares, repair

The value stream can be mapped at different levels including process level, single plant, multiple plants, across the company

2. Current State Drawing (To understand how the value currently flow)

After choosing the product family the current state of the value stream is described using the typical VSM symbols. It is not necessary to use the specific VSM symbols, if you have symbols that are more relevant/descriptive for your processes then use those.

Here is the step by step process of drawing the current state map:

- Show the Customer and gather information about customer demand

- Add the major Processes including the data such as cycle time, change over time, the available working time, the number of workers, defect rate, uptime information, , defect rates, and uptime information and so on.

- Show the Material Flow

- Show Information Flows

- Show Timeline

3. Future State Drawing (To make the flow LEAN)

To come up with a future process that is lean, we need to tackle the wastes to make our value stream LEAN. In order to identify the wastes and their root cause and to improve the value stream, you should improve the flow of material and information by:

- Reducing Long set-ups, Large distances, Downtime problems, Long lead times and so on.

- Produce at the rate customers’ demand your products (Takt Time)

- Applying continuous flow (one piece at a time instead of in batches)

- Applying supermarkets if the continuous flow is not possible. : A ‘supermarket’ links a process step to an upstream step which still needs to be run in batches.

- Schedule production at one specific step (Pacemaker process) as all the process steps are closely linked.

- Level the production mix if multiple types of products are produced in the same flow

- Level production volume by releasing fixed amounts of work onto the production department.

4. Develop Value Stream Plan and continual Improvement

In order to manage and monitor the required improvement action, a value stream plan is required. It may include the objectives, the required actions, due date, responsible person(s), etc.

The plan needs to be reviewed regularly while walking the floor by Value Stream Manager and Plant Manager to focus on obstacles to implementation. Making continuous Value Stream Improvement the responsibility of management.

How CBIS can help you

Please contact us if you need more details on how our expert team can assists you in training your team and developing your value stream maps.

What is DFSS? Design for Six Sigma is used to perfect products and processes before...

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma is a powerful method for improving existing products, processes and services. One...

What is a Kaizen Blitz? Kaizen definition has been Americanised to mean “Continual Improvement.” A...

As global competition continues to grow, the pressure to improve becomes more and more intense....

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.