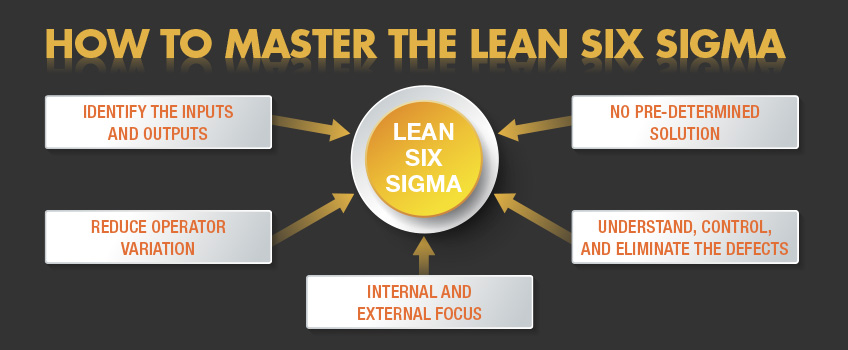

Lean Six Sigma is a powerful method for improving existing products, processes and services. One way to improve the deployment of lean Six Sigma is to improve how lean Six Sigma projects are identified and selected. The typical approach to lean Six Sigma project identification and selection is heavy on selection techniques but light on identification techniques.

A number of criteria can be used to select Lean Six Sigma projects:

- A project should have identifiable process inputs and outputs.

- A good project should never have a pre-determined solution. If you already know the answer, then just go fix it!

- For projects that have an operator or operator training as an input, focus on ways to reduce operator variation, thereby making your process more robust for different or untrained operators.

- All projects need to be approached from the perspective of understanding the variation in process inputs, controlling them, and eliminating the defects.

- There are two basic categories of projects, those with an external focus on improvement opportunities and those that have an internal focus on improving process efficiency.

External

The real focus of Lean Six Sigma is to provide near defect-free goods and services to the customer. To identify suitable projects, ask the following questions with the Voice of the Customer, Voice of the Market, and the Voice of the Process in mind.

- How or where are we not meeting our customer expectations today? (in either our business or manufacturing processes)

- What will our customers need in the future?

- What do we need to do to make our customers successful?

- What are the competitive threats?

- What is the contingency plan to address a competitive threat?

- Are our suppliers capable of providing the quality we need?

- How is the market changing, are we ready to serve emerging market needs?

- Do we have a clear and defined process to capture the Voice of the Customer?

Internal

Look for areas of trouble, frustration, or opportunities to improve. Talk to employees and management. Don’t just think about manufacturing process problems. Are the business processes working smoothly? Do you know where defects are hurting the business (billing, order entry, scheduling, etc.)? To find suitable projects, use the following:

- Internal Defects

- Efficiency/Capacity Issues

- Other Plant Cost Drivers or Measurables

- Material Utilisation

- Understanding Process Variation

- Maintenance

- Efficiency/Capacity Issues

Lean Six Sigma Roles and Responsibilities in identification and selection of lean six sigma projects

Executive Leadership Roles:

- Clearly articulate the strategic direction for the organisation

- Define the organisation’s priorities, what has to happen for the corporation to be successful, now and in the future

- Relentlessly support the Lean Six Sigma process

- Hold business leaders and Lean Six Sigma Champions accountable to deliver results

Champion Roles

- Identify projects most likely to succeed and have a high business impact

- Develop a strong business case for each project linking the project deliverables to the organisational goals (high-level goal alignment)

- Determine the critical success factors for each project

- Identify the key metrics to measure project progress

- Provide resources and work with process owners to facilitate team success

The most common mistakes in defining a potential project are:

- The scope is too broad (solving world hunger or boiling the ocean). Symptoms include too many output Y’s, multiple goals, numerous Process Owners, multiple departments.

- Solution: Divide the problem into several projects.

- The problem is too easy.

- The problem solution is known.

- It is a “just do it”; no problem analysis required.

- Problem is a management or market issue – not a good “Belt” project.

- Long term research or development project, not a problem to be solved with Lean Six Sigma tools.

How CBIS can help you

Please contact us if you need more details on our training and consulting services and how our expert team can assist to select and manage your Lean and Six Sigma projects successfully.

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

As global competition continues to grow, the pressure to improve becomes more and more intense....

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.